Name: Ruari Coles.

Kitcar history: Fiddled with VW-based ACM Bonito while at school, built an SSC Stylus with Dad in 1996-7 and now doing this. Started research in March 1999 (when there were hardly any bike powered cars around....). Have been lucky enough to spend the last few summers working at TVR (three times), Reynard (on Mondeo BTCC and Panoz) and TWR (on Clio V6 project).

Why build this car?: Final year degree project for an MEng at Oxford University, meant

to be 40% of year's work. Being done on behalf of both Sylva and Tom Lowther (one of

their customers). Sylva have provided the chassis (18swg) and Tom has provided all

the necessary R1 bits. Tom will eventually keep the finished car. The deadline

for my report is the beginning of June, by which I hope to have a complete (panelled)

rolling chassis with as many extra bits done as possible.

Where?: Work being carried out in the Oxford Engineering Dept.'s Osney Mead research

labs - on the first floor, so the car will need to be craned out....(!) Practically

every tool/machine available (if not on site then a mile and half across town in the main

engineering dept.), and if I can't use what I need (or don't want to) then there are lots

of friendly lab technicians happy to do jobs for me.

The Engine mounts are fabricated from Dural Plate and mild-steel.

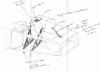

Here is a manual gearchange linkage. Due to the position of the gearshift arm on the bike-box a 90degree turn has to be made. This is achieved via a bellcrank system.

New improved Gearchange linkage

| Improved gear-lever bracket using the reverser box bracket | Detail of the lever base bracket |

The sprocket drive uses the standard bike cog. It consists of two plates which

encase the cog and use drive bolts connecting through the "teeth" of the cog.

The smaller half is steel, the other dural, and the aim is to weld an MGB-type prop

flange/UJ directly onto the steel half. The sprocket can float 5mm, and the

extension out of the back of the dural half is a tight fit round the R1's fatter output

shaft bit (which rotates with the sprocket) to prevent any rocking.

All the various welds on the props have been TIG welded. The UJ yoke shown stuck to the steel half of my prop adaptor is from the gearbox end of an Anglia prop (same UJs as the MGB) - with the long splined bit cut off you get left with a much smaller fitting as there's no big flange (as there is on both ends of the MGB prop).